Product description

Product description

A silicon-based additive consisting of multi-wall structured carbon nanotubes and silicon designed specifically for silicon-based products to achieve static dissipation and conductive applications

Product introduction

Product form: viscous paste

Resistivity: ~1Ωcm

Carrier: Vinyl-terminated polysiloxane

Carbon nanotube concentration: 1.5% by weight

Curing method: Consult your tree ester supplier to confirm the curing agent and curing conditions

Specific gravity: ~0.99

Color: black

If the required surface resistivity ≥ 106 Ω is added to the formulation, the carbon content will be extremely low, so it is common to equate ANTIS-SIL series silica-based additives to ethylene siloxane for stoichiometric calculations.

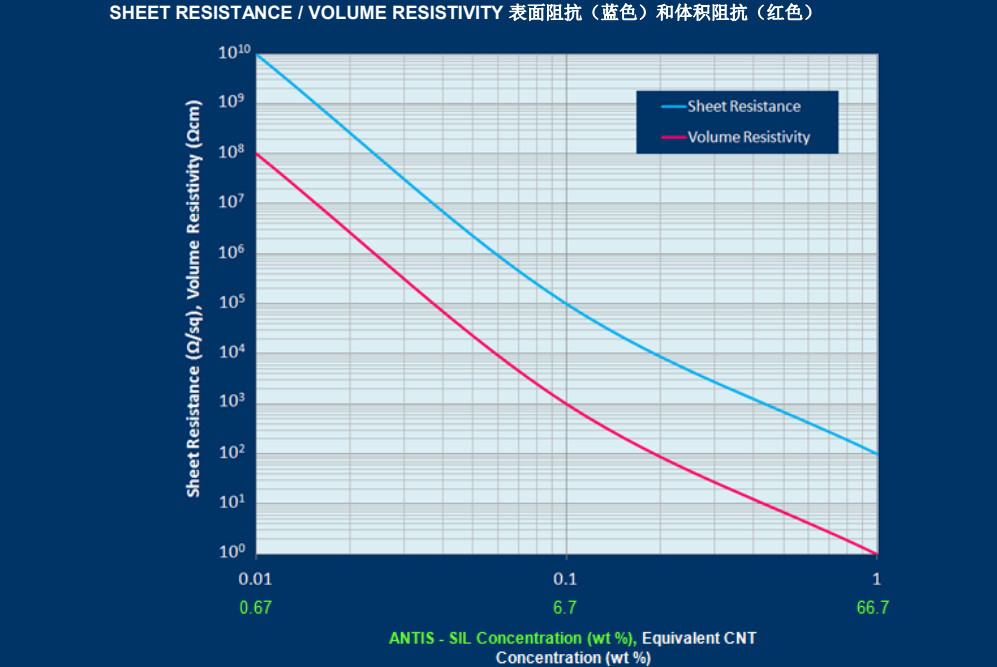

Surface or volume resistivity measurements are made on < 100 micron (< 4 mils) thick films using ANTIS-SIL, BLUESIL 621V1500 and curing agents (no pigments are used) and the resistance is measured after the sample is made according to the formulation. Surface or bulk resistivity may vary depending on the formulation, curing agent, film thickness and measurement conditions.

The wt% wt% of ANTIS-SIL in the above chart means the amount of ANTIS-SIL silica-based additive in the final product (compound). The calculation is as follows.

Example:

ANTIS-SIL additive at 5 wt % is the final product (compound) using 5g of ANTIS-SIL additive and 95g of silicone and curing agent. The ratio of siloxane to curing agent must be done according to the supplier's requirements.

Product Applications

ESD/anti-static protection

Surface coating and painting

Electromagnetic compatibility and electromagnetic shielding

Conductive inks

Adhesive Products

User's Guide

1.Low viscosity products

A clean, properly sized mixing vessel should be prepared prior to diluting the original batch of ANTIS-SIL silica-based additive - the vessel should be 3-4 times the total volume of the mixture. For best results, use an electronic scale of suitable accuracy to ensure accurate measurement.

Use a mechanical mixer until the mixture is well blended. During this time, check the mixing blades and the surface of the container for unmixed material buildup, and if there is any buildup, dispose of it promptly to achieve a homogeneous mixture. For best mixing results, we recommend the use of high shear mixing blades with a mixing speed of about 1500 rpm.

If necessary, for products with less than 5% of additives, the proportion of additives can be gradually reduced by adding the raw material in several steps to achieve the best mixing effect. For example, first mix 5% of ANTIS-SIL additive with a certain percentage of the main material, and then pour the remaining main material into the mix when the mixing is complete. After mixing, it is recommended to defoam (up to 10 minutes at 100-200 RPM) and finally empty the container or add other materials such as colorants.

Shelf life (final product (compound) after mixing): This should be confirmed based on actual test results, taking into account the differences in the main ingredients and the mixing ratio. However, in order to ensure the best use of the product, timely use is recommended.

2.High Viscosity ProductsDilution of the original batch of ANTIS-SIL silicone based additives is recommended in a universal mixer (e.g. double drum type) coupled with a special Brabender compactor to ensure that the various materials with high viscosity are mixed well. Regarding the mixing time, it is determined by the specific characteristics of the material. For high viscosity products, the supplier recommends the use of ANTIS-SIL silica-based additives at 5-10% by weight to achieve a surface impedance of 107-105 Ω/sq.

Measurement impedance

The current is usually very low when measuring the resistance of thin layers of electrostatically dissipative coatings (>106 Ω). It is important to use highly sensitive measurement equipment, such as a megohmmeter with a 5-lb resistance probe that meets the requirements of ASTM F150 or a DC four-point probe analyzer with silver-plated electrodes that meets the requirements of ANSI/ASTM D257. In both cases, the electrode has a much lower resistance than the sample, so care should be taken to prevent sample contamination (in the case of silver-plated electrodes).