Product description

Product description

A thermoplastic additive designed specifically for thermoplastic products to achieve static dissipation and conductive use, consisting of carbon nanotubes with a multi-wall structure and paraffin oil.

Products

Product form: viscous paste

Carrier fluid: white paraffin mineral oil

Carrier fluid boiling point: 274℃

Carbon nanotube concentration: 1.5% by weight

Specific gravity: ~0.99

Color: black

Carrier solvent/diluent: None

If the required surface resistivity ≥ 106 Ω is added to the formulation, the carbon content will be extremely low, so the ANTIS-TP series thermoplastic additives are usually equated to paraffinic mineral oil for stoichiometric calculations.

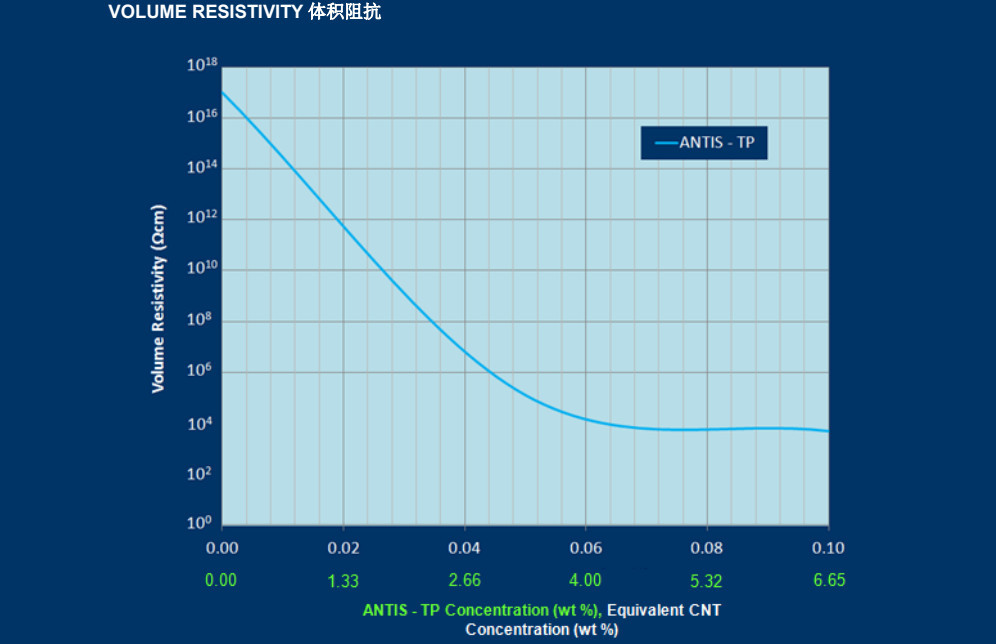

The volumetric resistivity is measured by mixing ANTIS-TP with PP powder and then mold casting the specimen for testing. The volume resistivity may vary for different alkali polymers.

The wt% weight percentage of ANTIS-TP means the amount of ANTIS-TP thermoplastic additive in the final product (compound). It is calculated as follows.

Example:

The weight percentage of 5 wt . % of ANTIS-TP thermoplastic additive i.e. - the final product (compound) using 5 g of ANTIS thermoplastic additive and 95 g of PP powder.

Product Applications

ESD/anti-static protection

Batteries and Fuel Cells

3D Printing Materials

Antistatic Plastic Film

Electronic Product Packaging

Conductive Wires

Conductive fibers

Smart Vehicles

User's Guide

Method 1

The polymer pellets and/or powder are mixed with the ANTIS-TP thermoplastic additive in wet powder mixing equipment (e.g., belt mixer) until the ANTIS-TP thermoplastic additive is uniformly coated on the plastic pellets and/or powder.

The polymer/ANTIS-TP blend can then be melt blended using plastics processing equipment (e.g., single-screw or twin-screw extruder).

Method 2Melt mixing of polymer pellets and/or powders with ANTIS-TP thermoplastic additive directly in a plastics processing machine such as an extruder (e.g., single-screw or twin-screw extruder) ANTIS-TP thermoplastic additive can be introduced into the extruder system using a liquid/paste injector/feeder

Measurement impedance

The current is usually very low when measuring the resistance of thin layers of electrostatically dissipative coatings (>106 Ω). It is important to use highly sensitive measurement equipment, such as a megohmmeter with a 5-lb resistance probe that meets the requirements of ASTM F150 or a DC four-point probe analyzer with silver-plated electrodes that meets the requirements of ANSI/ASTM D257. In both cases, the electrode has a much lower resistance than the sample, so care should be taken to prevent sample contamination (in the case of silver-plated electrodes).