Product description

Product description

A rubber additive consisting of multi-walled carbon nanotubes and paraffin oil designed specifically for rubber-based products to achieve static dissipation and conductive use

Products

Product form: viscous paste

Carrier solution: white paraffin mineral oil

Carrier solution boiling point: 274 ℃

Carbon nanotube purity: 1.5% by weight

Specific gravity: ~0.99

Color: black

Carrier solvent / diluent: None

If the required surface resistivity ≥ 106 Ω is added to the formulation, the carbon content will be extremely low, so the ANTIS-RB series rubber-based products are usually equated to paraffinic mineral oil for stoichiometric calculations.

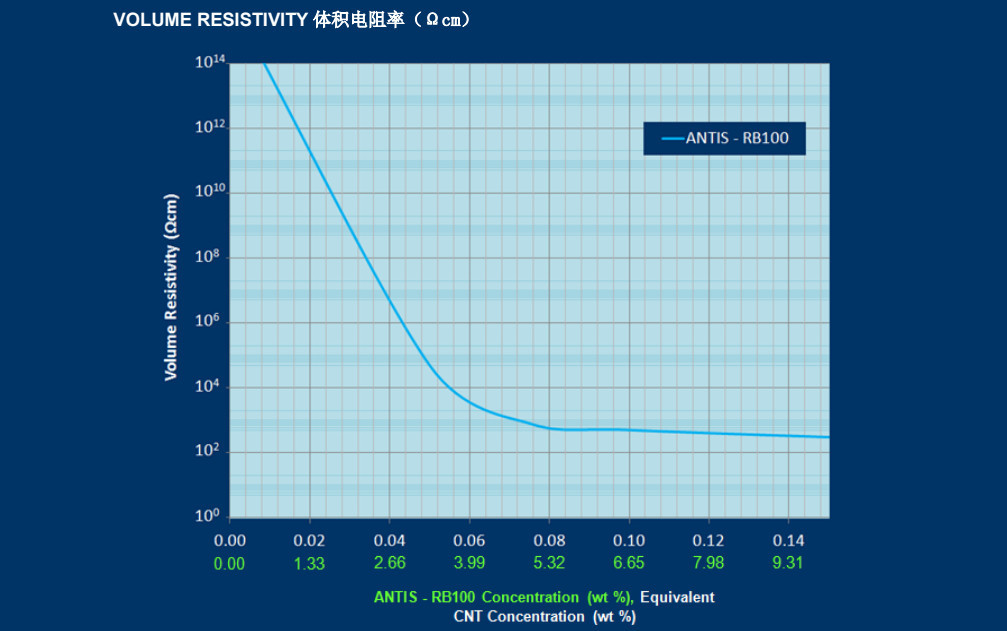

Volume resistivity is measured by applying ANTIS-RB with EPDM rubber and curing agent (no pigments) to a 100 micron (4 mil) thick film and then measuring the resistance according to the formulation. The volumetric resistivity may vary depending on the formulation, curing agent, film thickness and measurement conditions.

The wt% (weight percentage) of ANTIS-RB in the above graphs refers to the amount of ANTIS-RB rubber additive in the final product (compound). It is calculated as follows.

Example: 5% by weight of ANTIS-RB rubber additive used in the final product

| Formulation ingredient name | (Recipe weight) |

| EPDM Rubber | 100g |

| Paraffin oil | 5g |

| Other materials | 30g |

| ANTISTM - RB | 7.7g |

| Curing agent | 10g |

Product Applications

ESD/antistatic protection

Industrial piping and fittings

Electromagnetic compatibility and electromagnetic shielding

Antistatic Rubber Lining

Personal Protection Products

Railroad industry

Construction industry

Automotive industry

Marine industry

User's Guide

The ANTIS-RB series of rubber-based additives can be mixed using common mixing equipment, but it is important to ensure that the additive is well mixed with the raw rubber and all other ingredients. We recommend using 5-10% by weight of our ANTIS-RB products to achieve a surface impedance of

of 107-105 Ω/sq (106-104 Ωcm).

Measurement impedance

The current is usually very low when measuring the resistance of thin layers of electrostatically dissipative coatings (>106 Ω). It is important to use highly sensitive measurement equipment, such as a megohmmeter with a 5-lb resistance probe that meets the requirements of ASTM F150 or a DC four-point probe analyzer with silver-plated electrodes that meets the requirements of ANSI/ASTM D257. In both cases, the electrode has a much lower resistance than the sample, so care should be taken to prevent sample contamination (in the case of silver-plated electrodes).

Next

Next